Rethinking

Fiber Optic

Cable Installation

Pitfalls to Avoid

for a Reliable Network

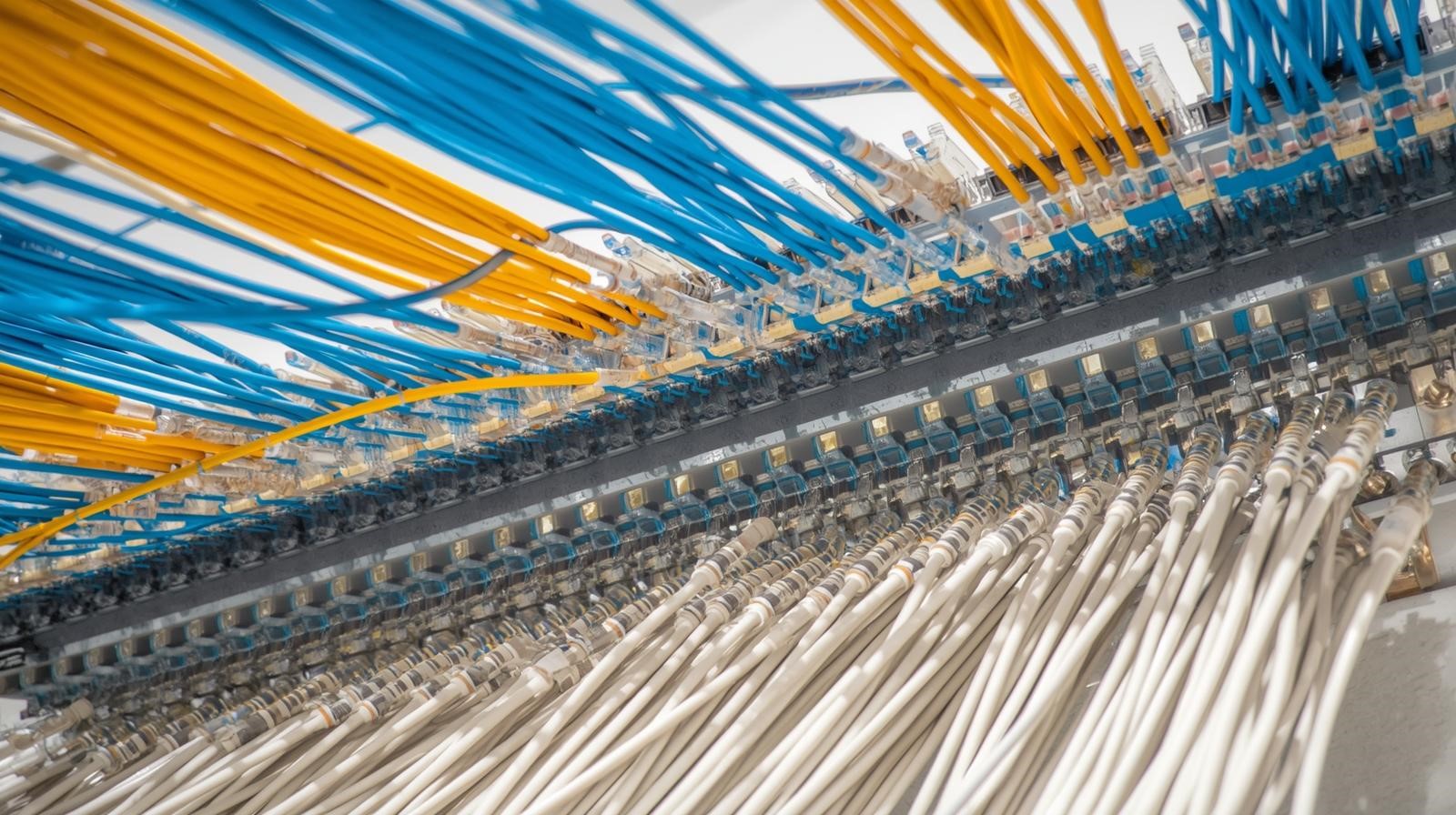

Fiber optic cables form the backbone of today’s high-speed digital networks, but working with them involves crucial care, distinct from handling traditional copper cables. Missteps during installation or maintenance can have lasting effects on network performance and equipment longevity. Below are key fiber optic cable handling mistakes to watch out for—and how to sidestep them.

Recognizing

FIBER'S UNIQUE NATURE

Fiber optic cable may resemble copper in its external form, but the similarities end at first glance. While both types travel in reels and may run side by side across data centers or office ceilings, the internal glass fibers at the heart of fiber optic cable are far less forgiving than metal wires. Treat them accordingly, with heightened sensitivity to stress and environment.

Planning Your Route: Avoiding Shortages and Strains

Among common pitfalls, the simple act of cutting cable too short stands out. Unlike copper, fiber can’t simply be joined or repurposed with a twist; connectors require careful preparation. When planning your cable pathways:

Carefully measure total distance, accounting for curves, vertical drops, and service slack at both endpoints.

Always allow additional length for routing, future moves, and unforeseen obstacles.

Cutting corners (literally or figuratively) can leave you with cable runs that just don’t reach.

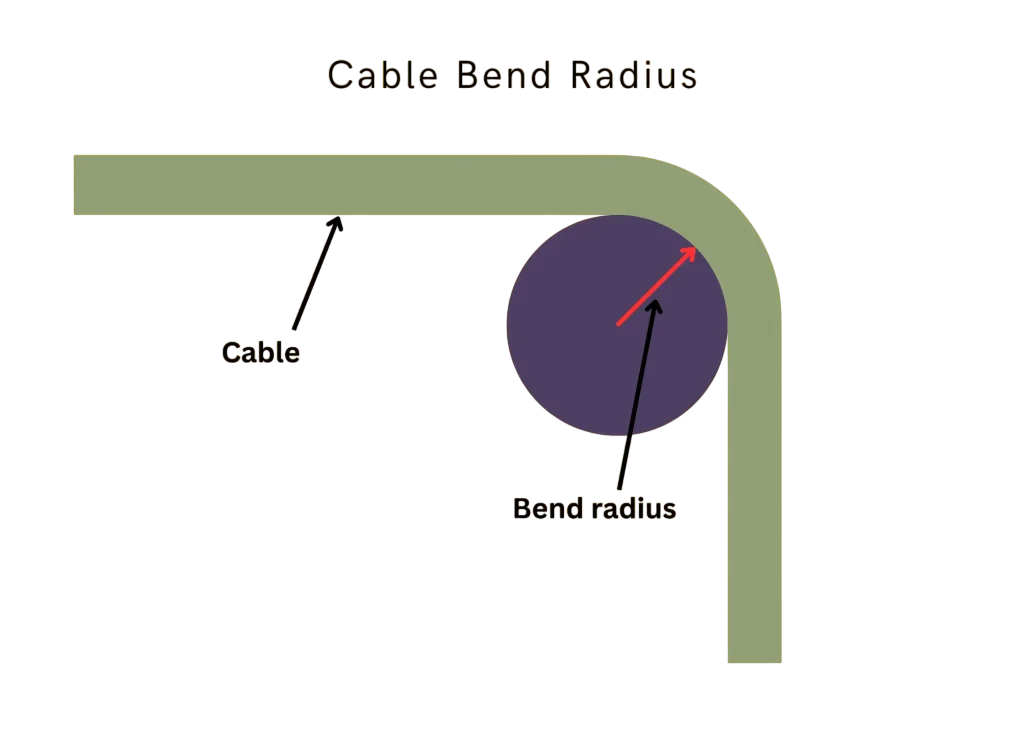

The Bending Conundrum: Respect Minimum Radii

Optical fibers have a minimum bend radius—exceeding it can break the glass or degrade signal transmission. Even “bend-insensitive” fiber is not immune from harm when bent too tightly:

Use sweeping bends and large conduit arcs.

Avoid sharp turns, pinches, or compressing cables during and after installation.

Keeping Twisting at Bay

Unlike copper, fiber optic cable doesn’t react well to twisting. Internal glass cores are brittle and can fracture easily, leading to invisible and costly performance issues.

To minimize risk:

Use a swivel attachment for pulls, especially if sharing conduit with other cables.

Prevent kinks by rolling cable out in a figure-eight pattern for longer runs.

Skip the

MAKESHIFT SUPPORTS

Improper pathways—such as D-rings, bridal rings, or crowded basket trays—can spell disaster for fiber. Support fiber cables adequately and avoid stacking or sandwiching them under heavier cables:

Use supports that distribute weight evenly.

Keep fiber separated from power cables and avoid unnecessary mechanical stress.

Don't Overlook Cleanliness

The #1 source of most fiber optic installation failures is contaminated connectors. Dust or oils—even those barely visible—can block or scatter light within the core:

Always clean connectors before making terminations or connections.

Use lint-free wipes and recommended solutions.

By recognizing these often-overlooked missteps, installers can avoid expensive rework, downtime, and disappointing network performance.

Treat fiber optic cables as the precision components they are—and happy networking!

Fiber optic cable installation demands precision and care to safeguard network integrity. Expanding from the initial guidelines, a few deeper considerations highlight just how critical these details can be.

Bending Specifications and Real-World Examples

During installation, always maintain a bend radius at least 20 times the cable diameter while under tension, and 10 times the diameter once installed.

For example, with a fiber having an outer diameter of 8 mm, ensure bends do not go below a 160 mm radius during installation and 80 mm after. Exceeding these limits causes microfractures, permanent attenuation, and shortened cable life.

Specialized bend-insensitive fibers can allow for slightly tighter curves, but manufacturer guidelines should always be followed.

Cable Routing, Environments & Compliance

Meticulous route planning isn’t just about distance; consider the environment—humidity, heat, and available trays can affect the laying and lifespan of fiber.

Adhering to national standards (such as TIA-568 or ISO 11801), and always consulting cable datasheets is fundamental for both compliance and warranty protection.

In data centers or crowded office runs, using bend-insensitive fiber types such as G657A2 or B3 may prevent future headaches, but still, each installation scenario demands a fresh check of documentation for optimal results.

Long-Term Reliability Through Preventative Measures

The way you handle, clean, and store your cables directly affects long-term reliability. Use bend-radius guide charts when working onsite.

Conduct post-installation inspections and document your work.

Fiber optic networks rely on careful adherence to bending, cleanliness, and support protocols at every step.

Expanded Safety & Performance Insights

Avoid installing fiber in extreme conditions without proper manufacturer consultation, as freezing temperatures can make the cable more brittle.

Always remove cut glass shards immediately and dispose of them in specifically marked containers.

Electrical interference is rare for fiber, but keep cables protected from physical threats and damage by sharing trays intelligently.

The Bottom Line

Fiber optic technology brings immense advantages, but reaping its rewards requires respect for its unique fragility. Handle cables with care, follow best installation practices, and maintain strict cleanliness to ensure network reliability for years to come.